Uniform Line

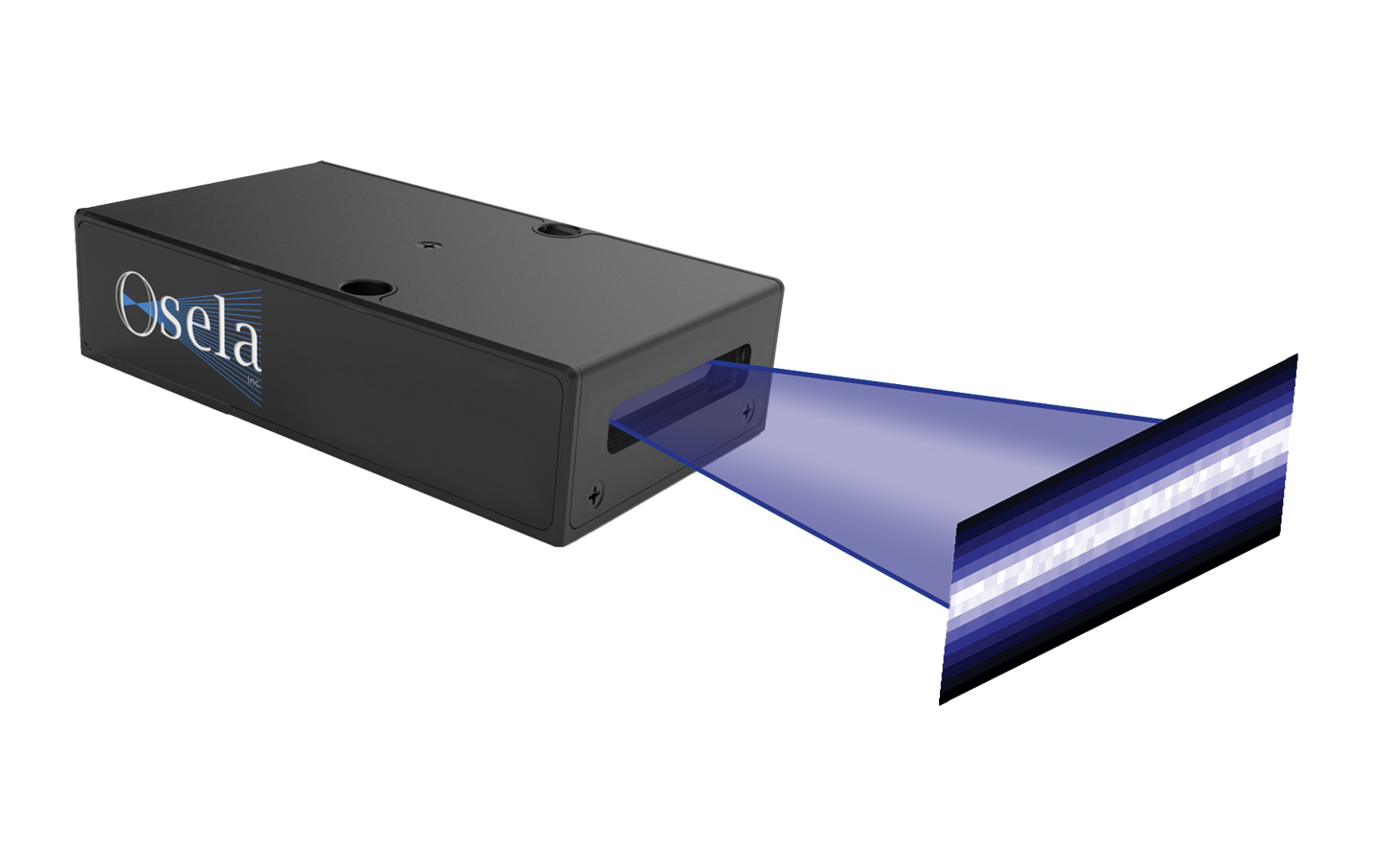

Highly characterized laser line projection technology optimized for your application

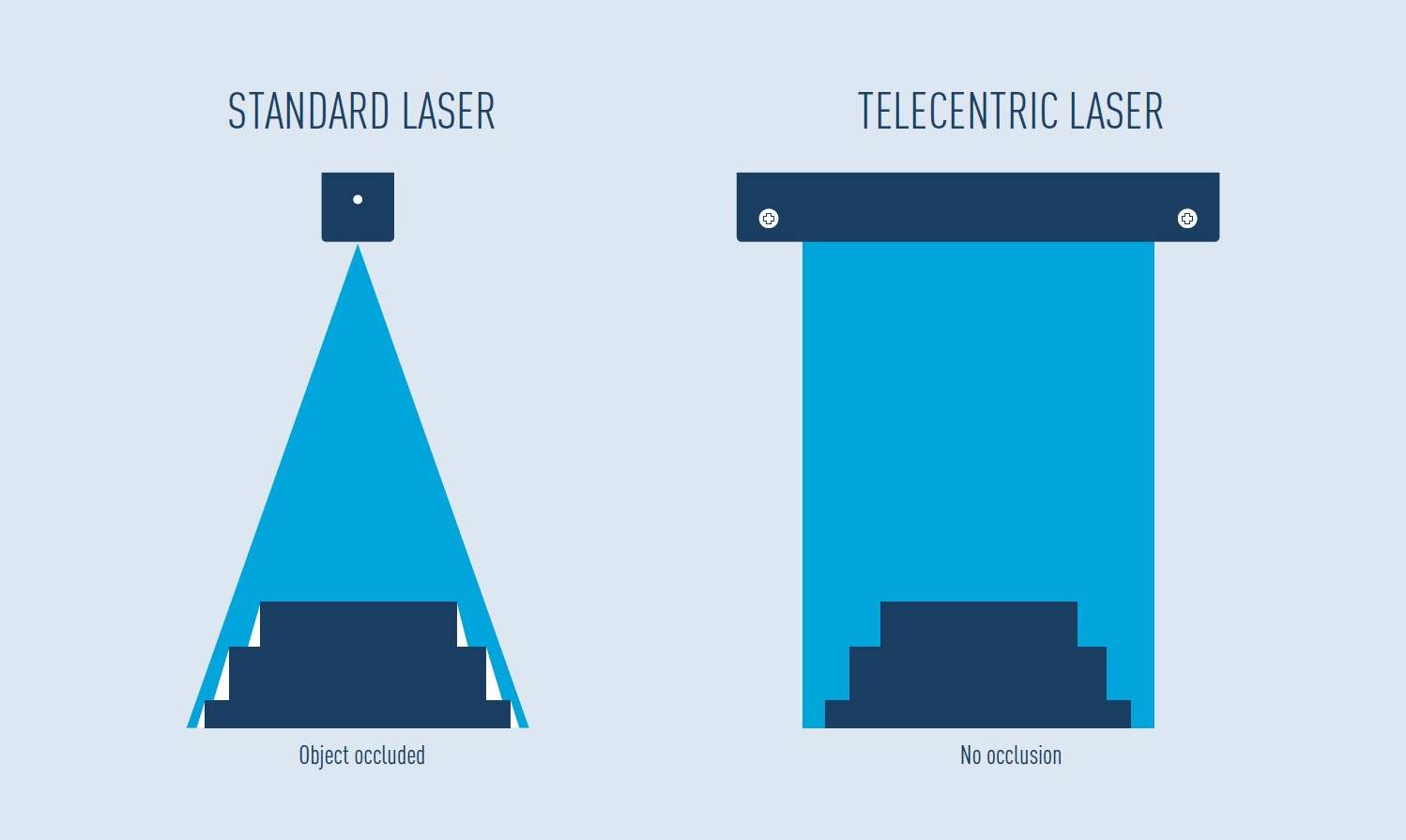

At Osela, we understand that a laser line is not just a laser line, as each application and system has its own specific illumination requirements for optimal performance. Our unique capabilities and expertise in laser beam shaping allows us to manufacture system specific laser line projectors. In-house lens manufacturing gives us tight control over performance and quality with industry leading laser line characterization techniques.

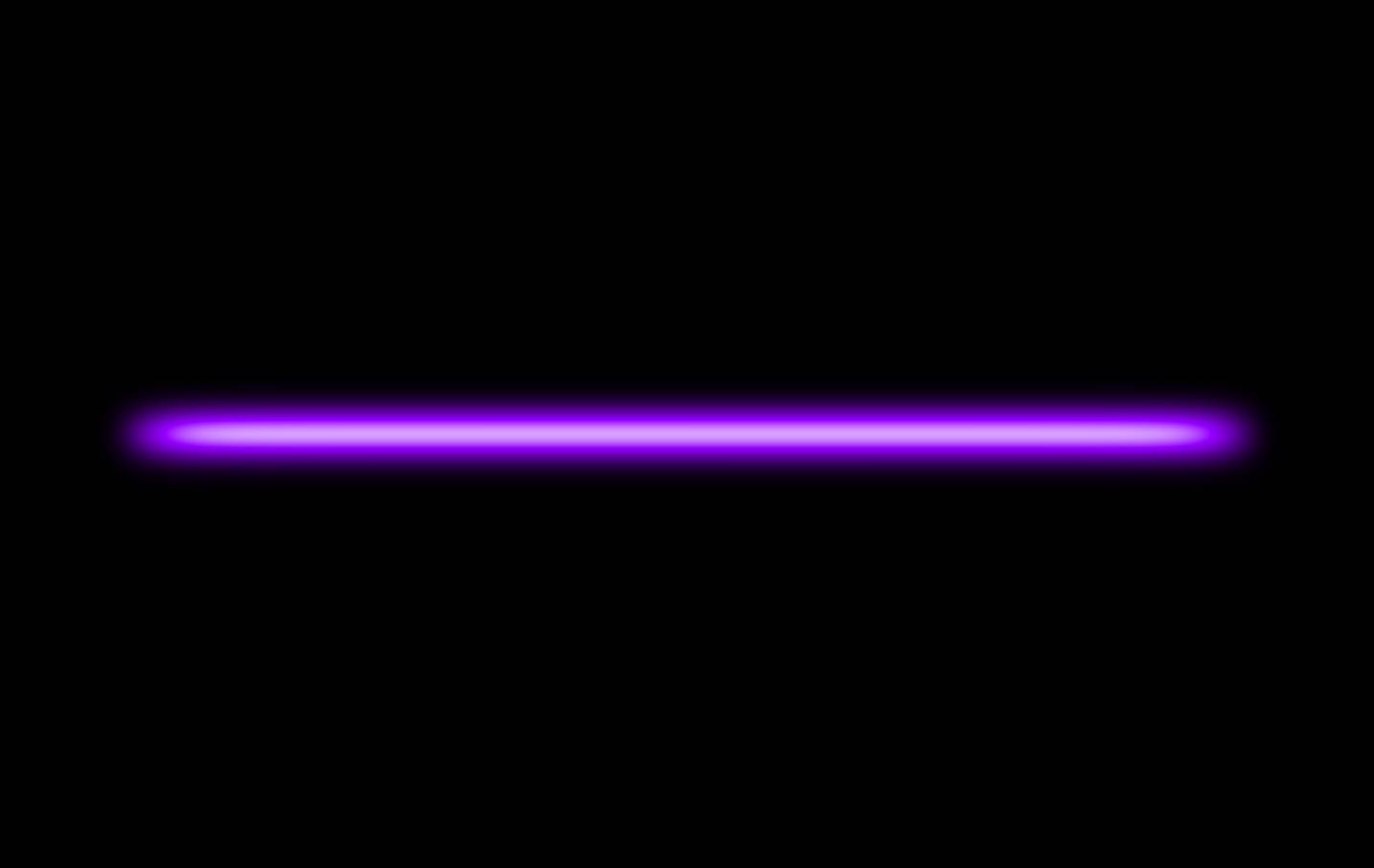

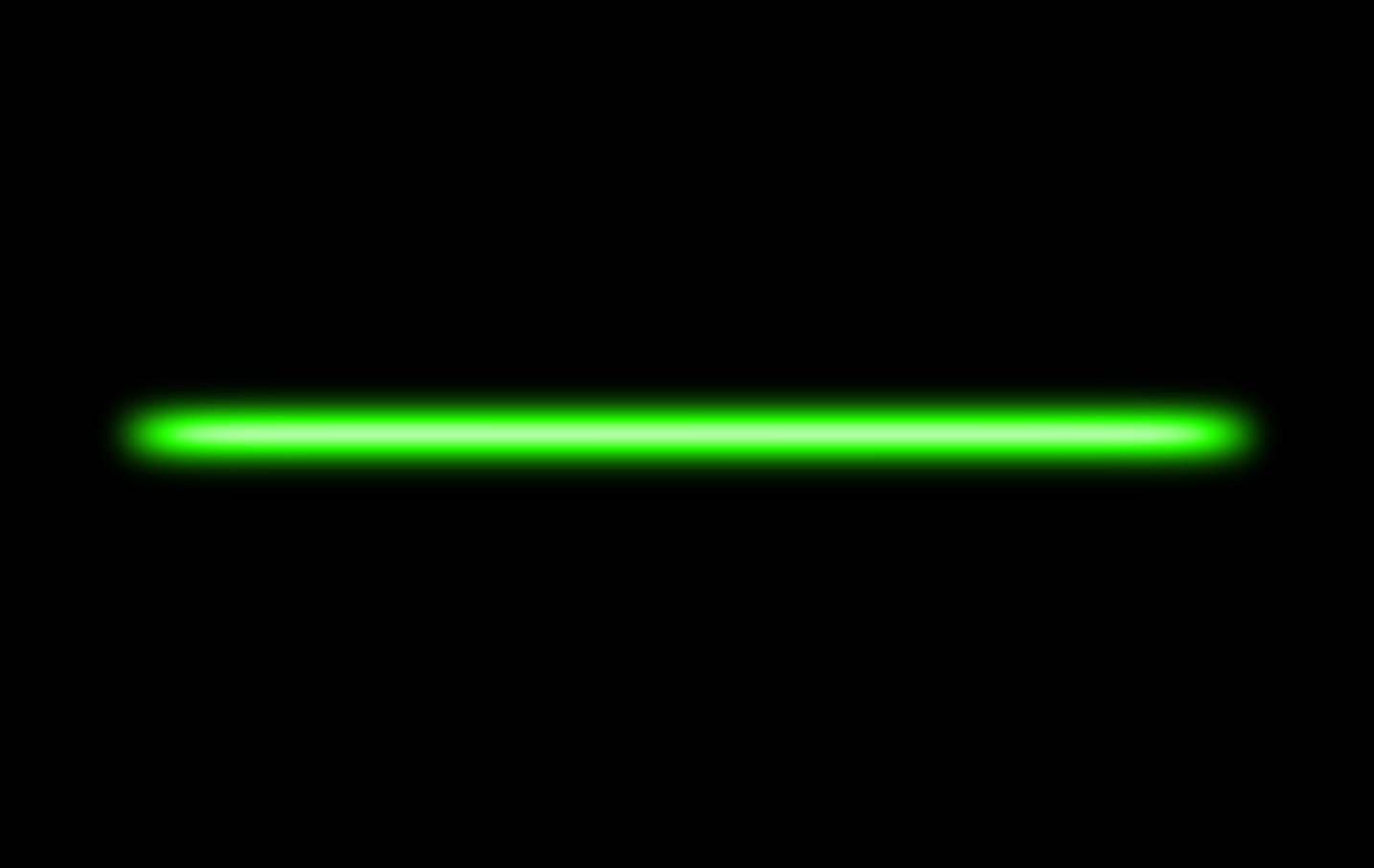

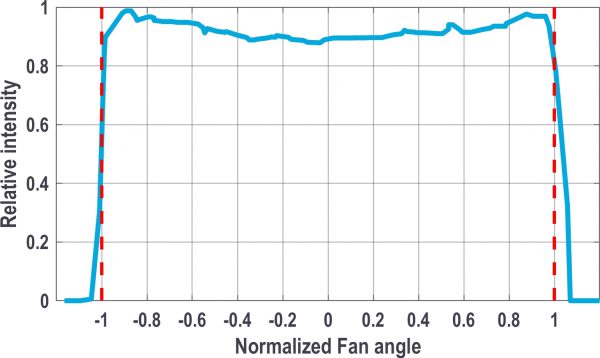

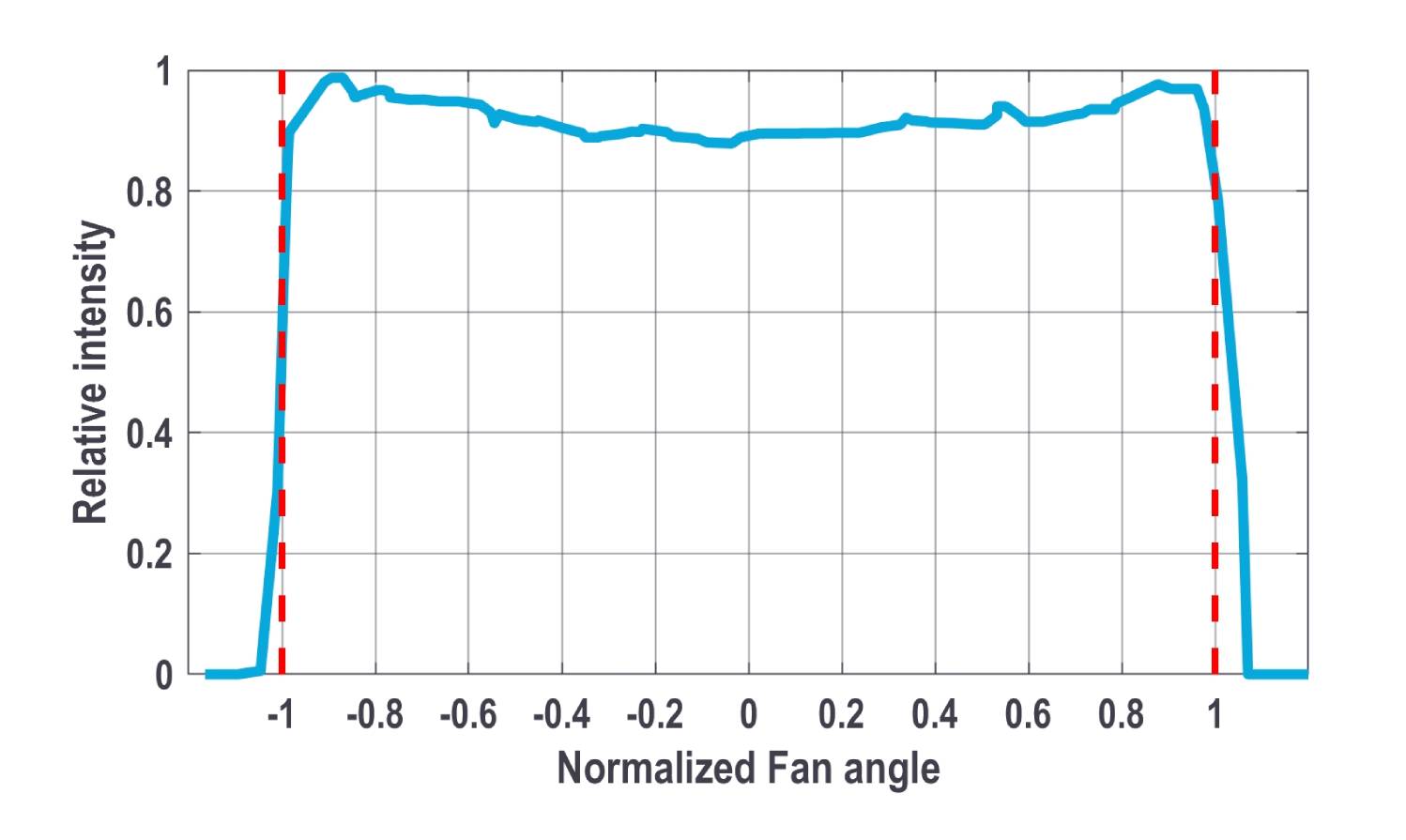

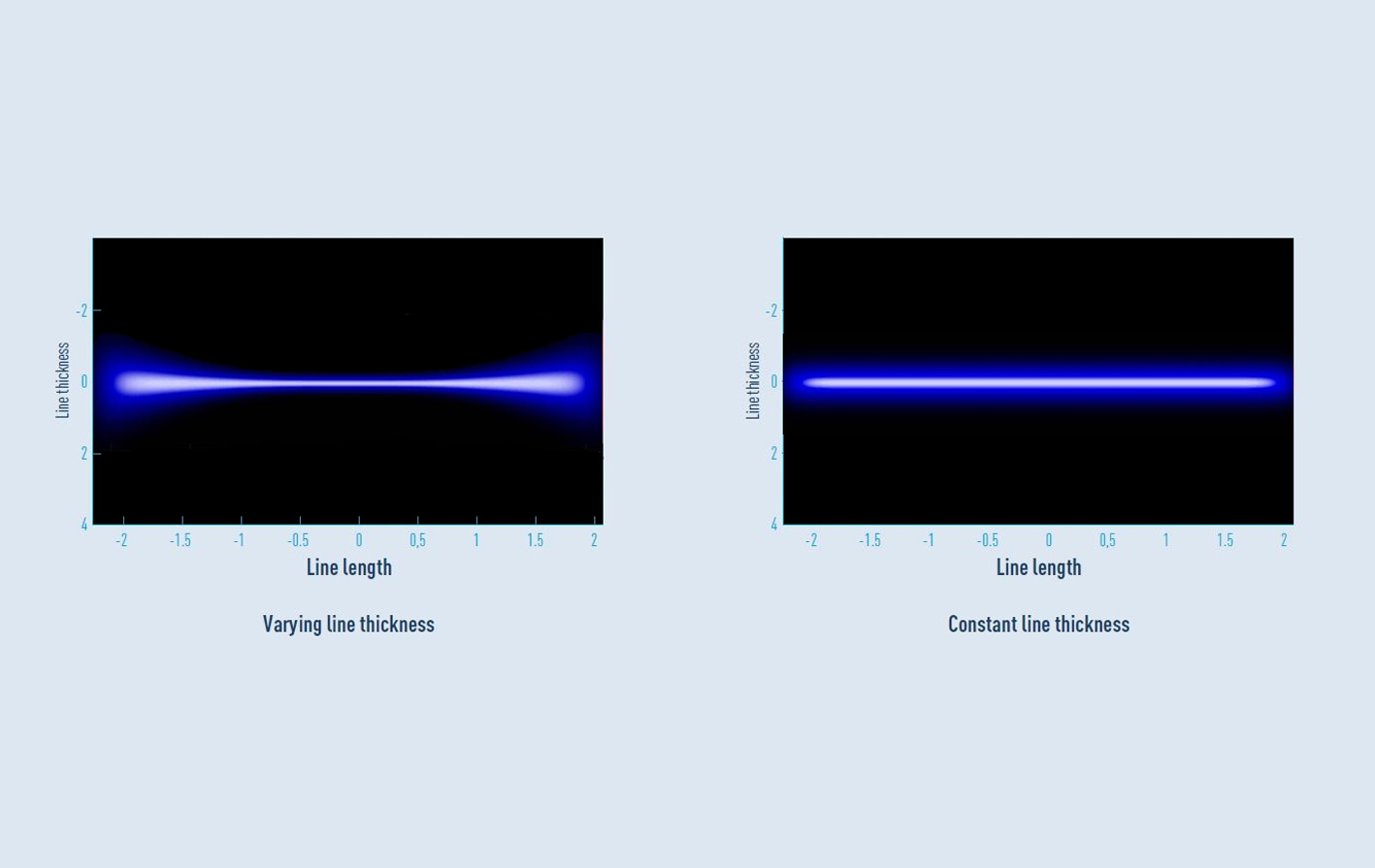

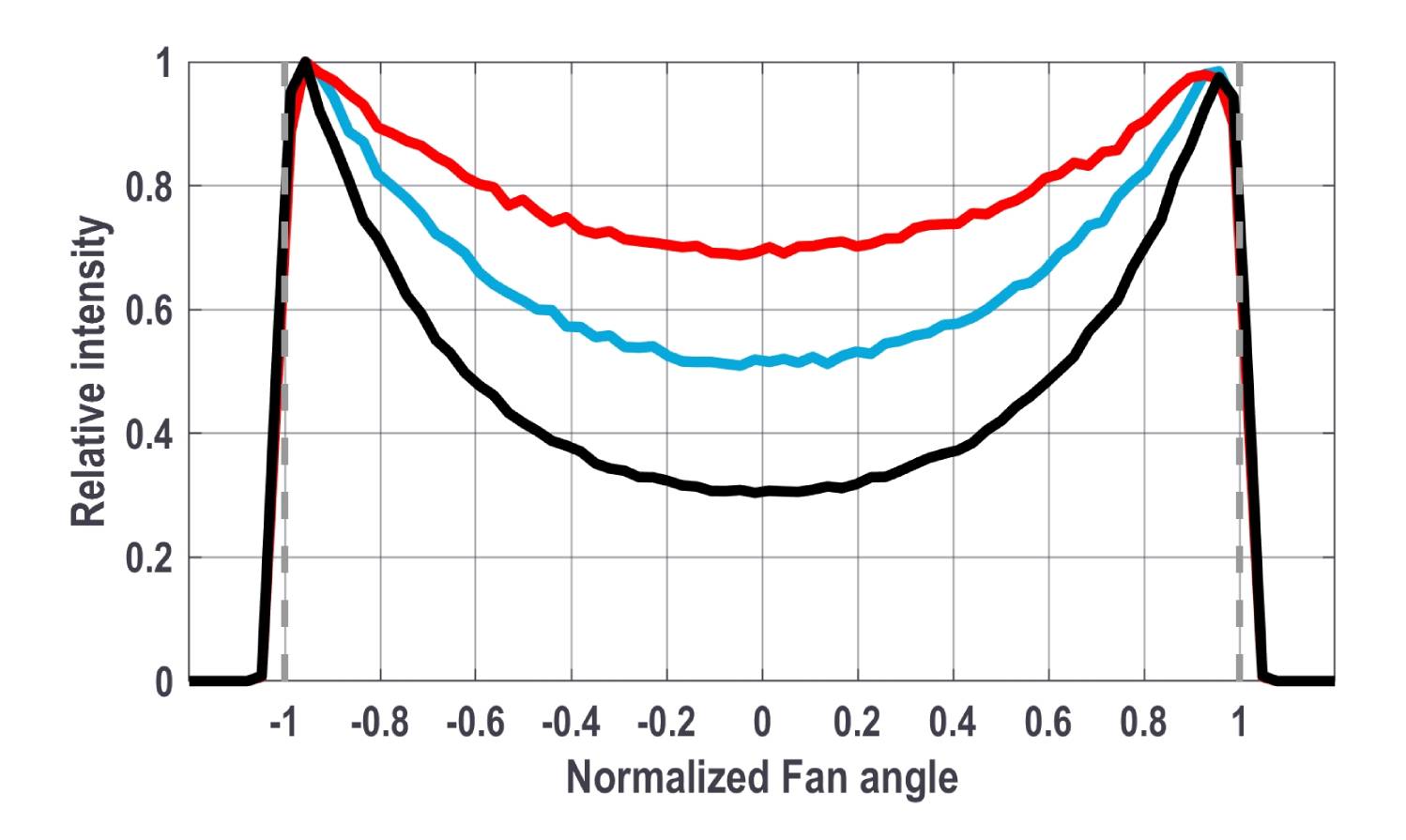

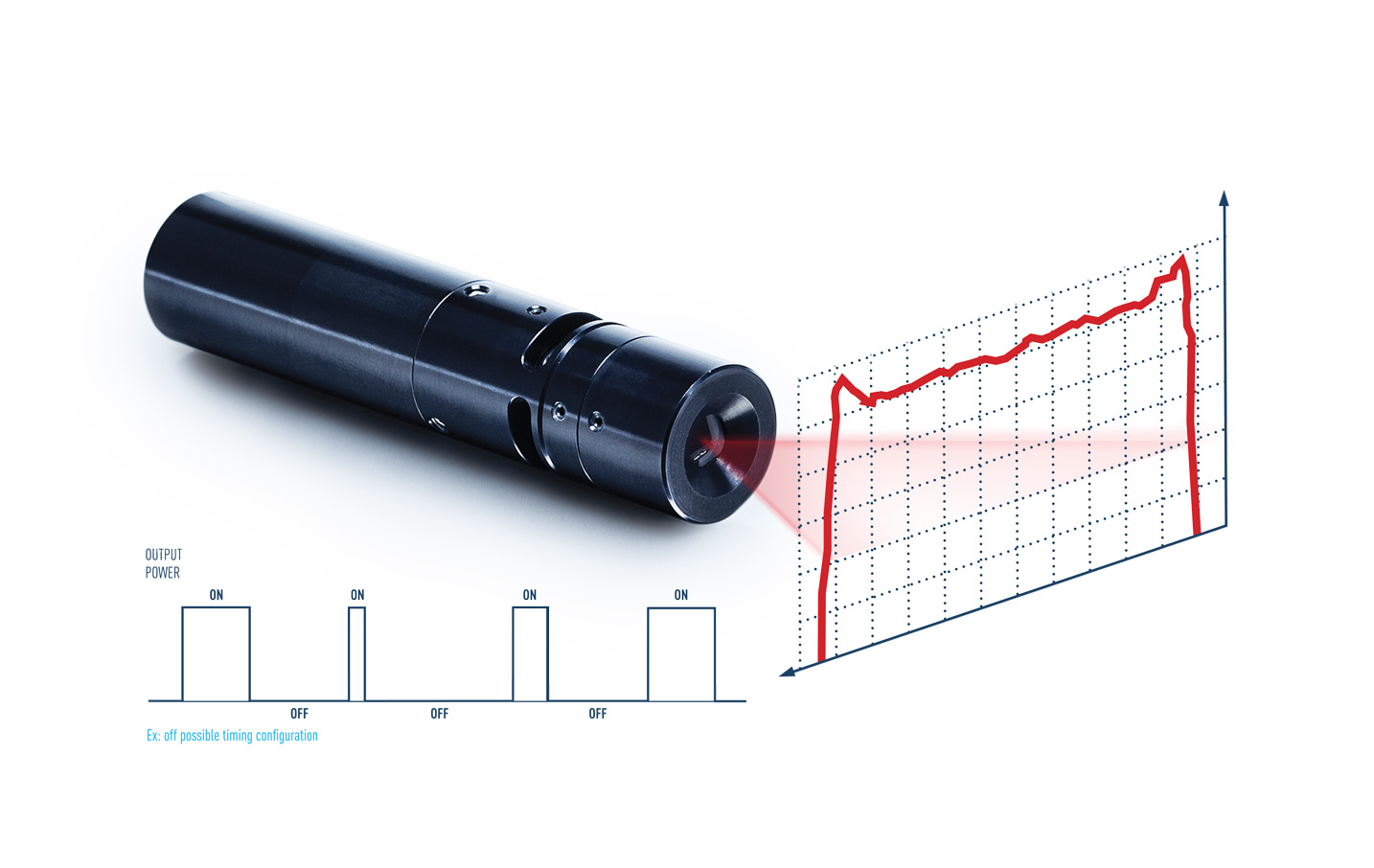

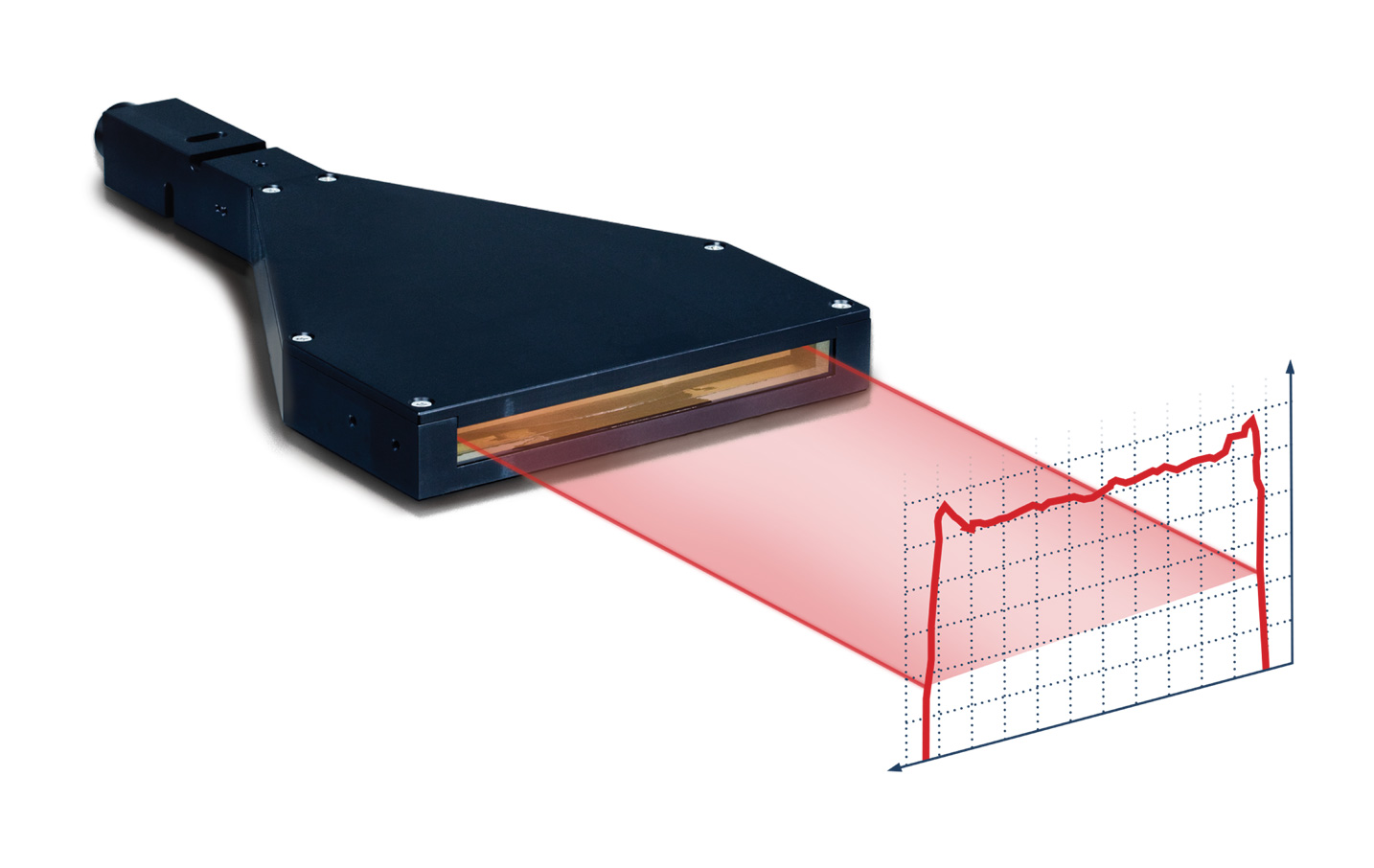

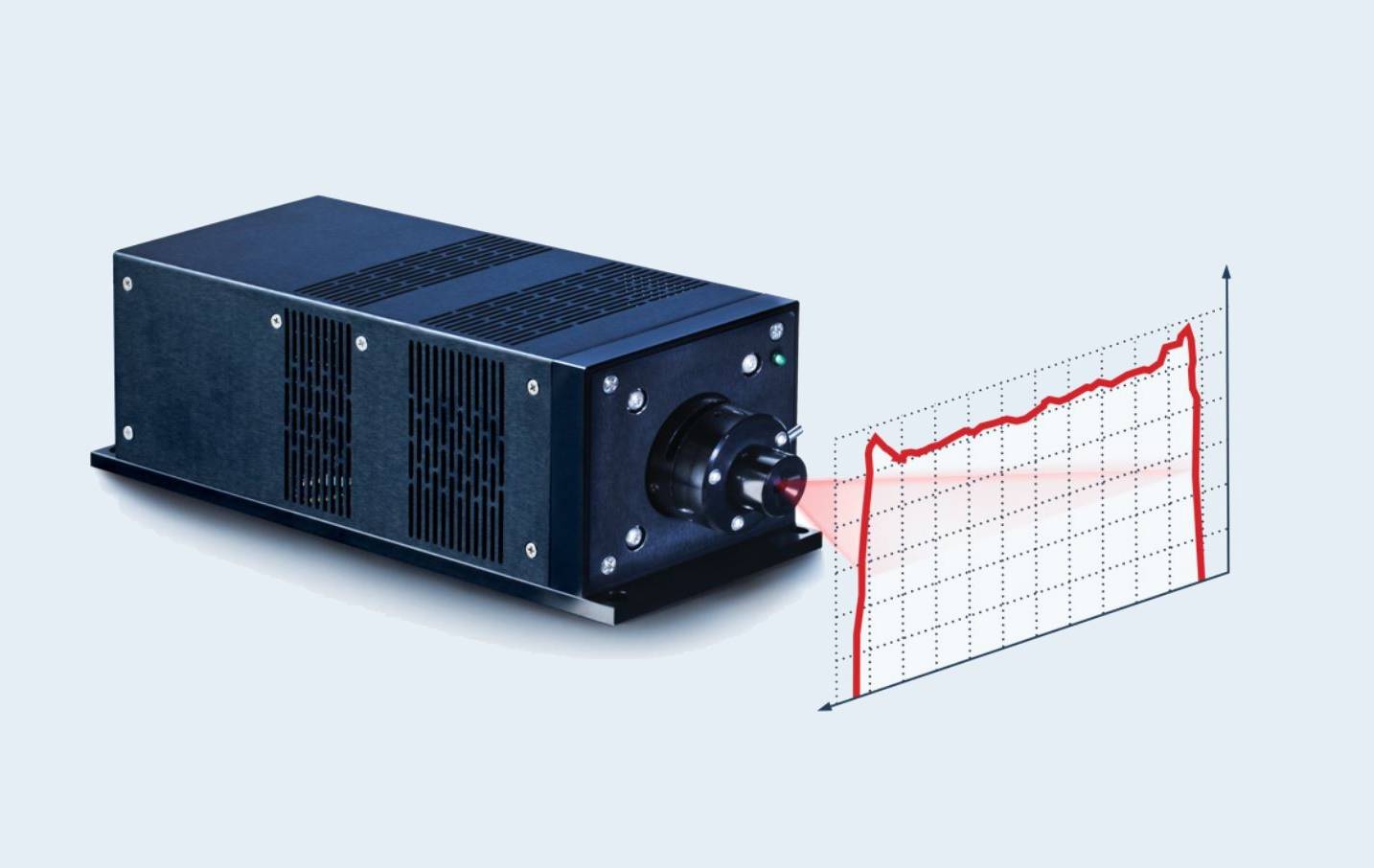

Line Uniformity

Our in-house optics manufacturing allows us to create laser line projectors with very specific power distributions. From highly uniform lines to cosine corrected distributions to purposely cambered profiles for incident angle projections.

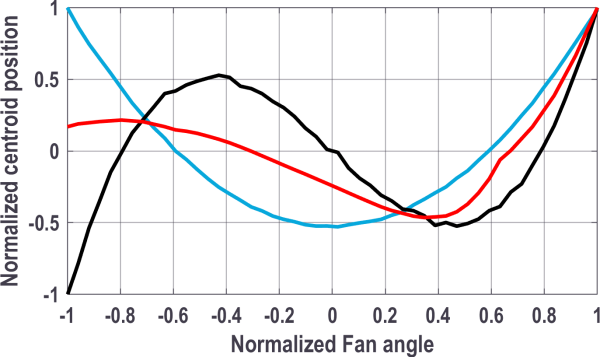

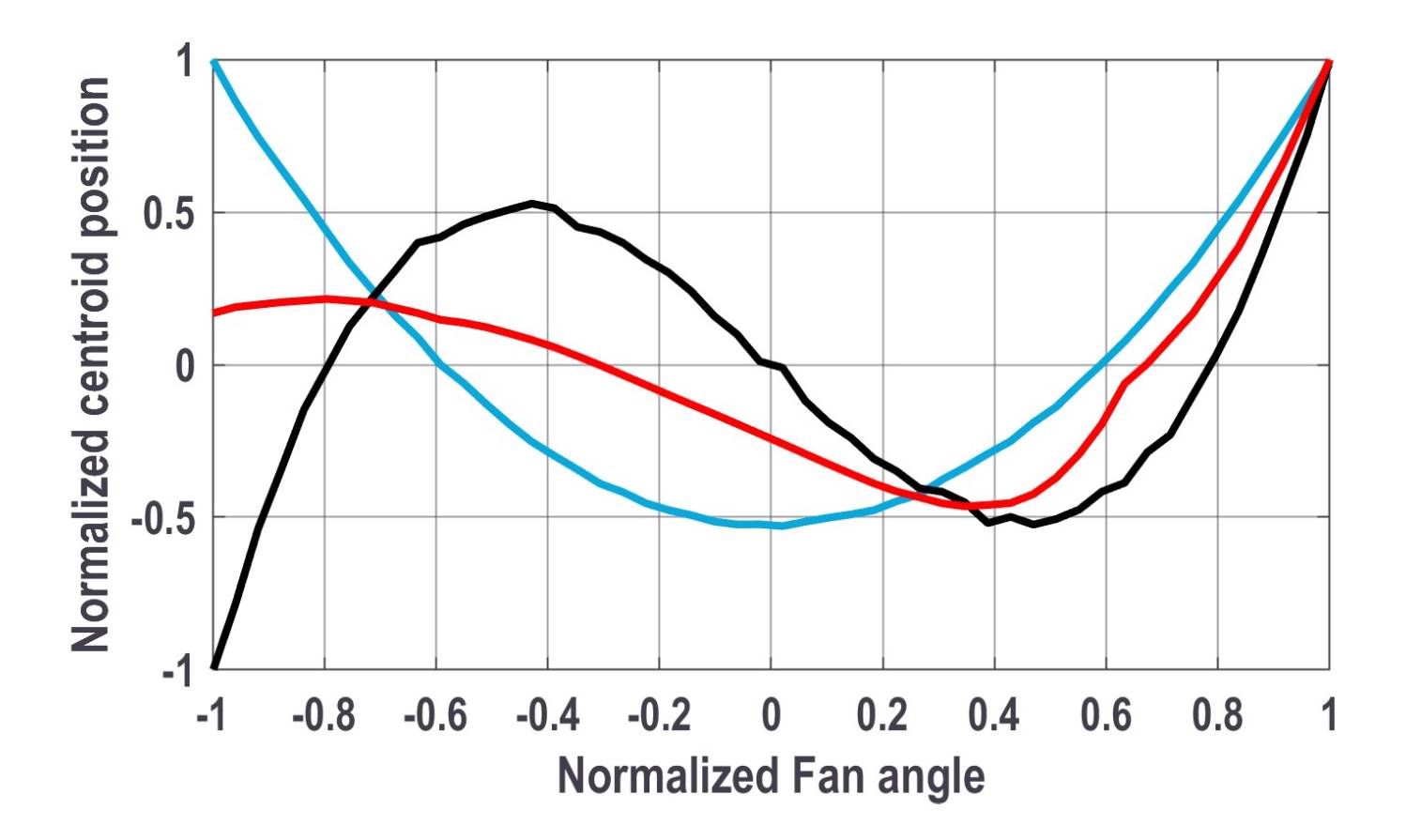

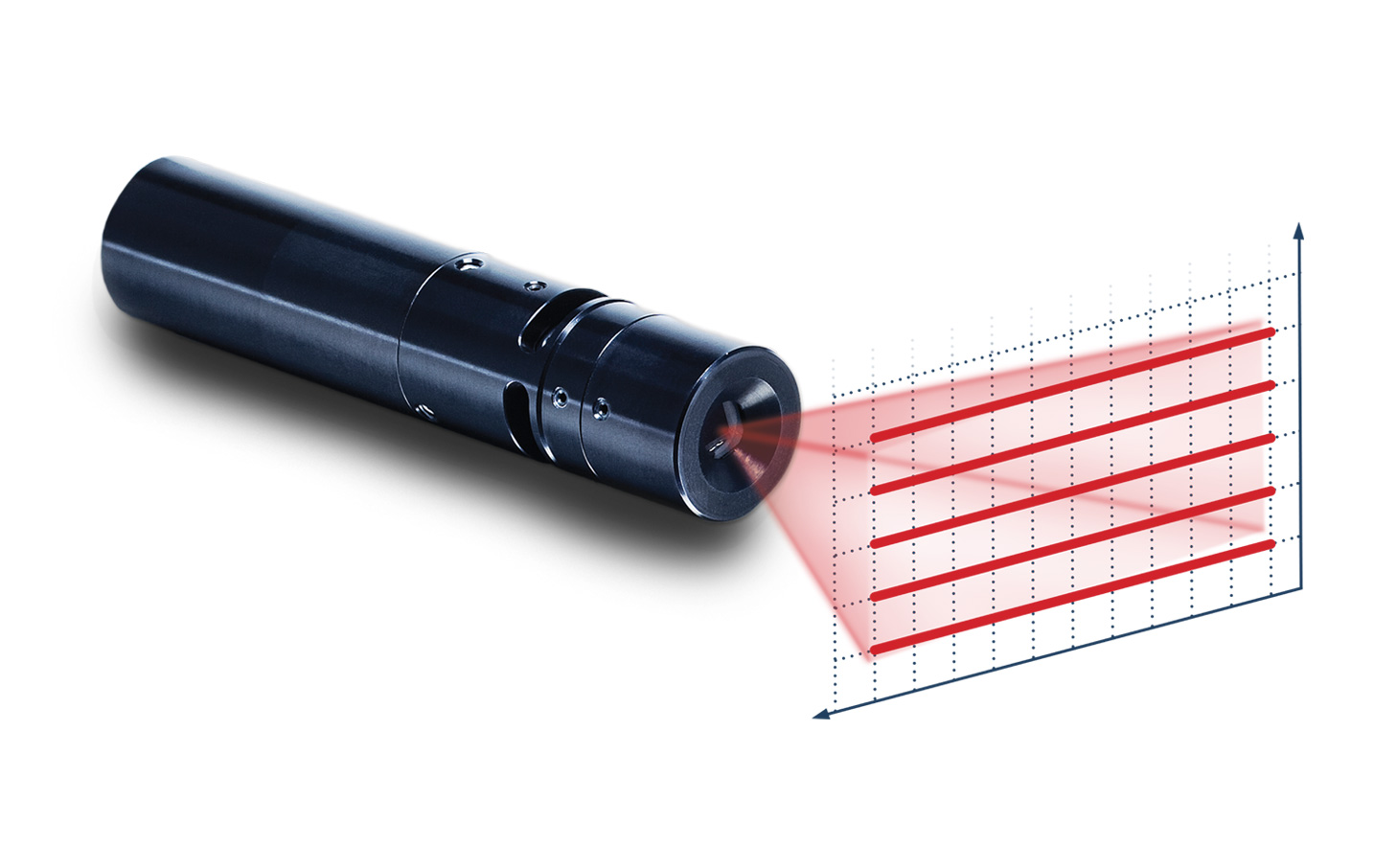

Line Straightness

Our characterizations techniques and optical train design allow for delivering repeatable laser straightness performance. With specifications down to < 0.03% deviation, we can meet the highest precision requirements. We can also manufacture according to straightness profiles with specific degrees of polynomial for easier software compensation.

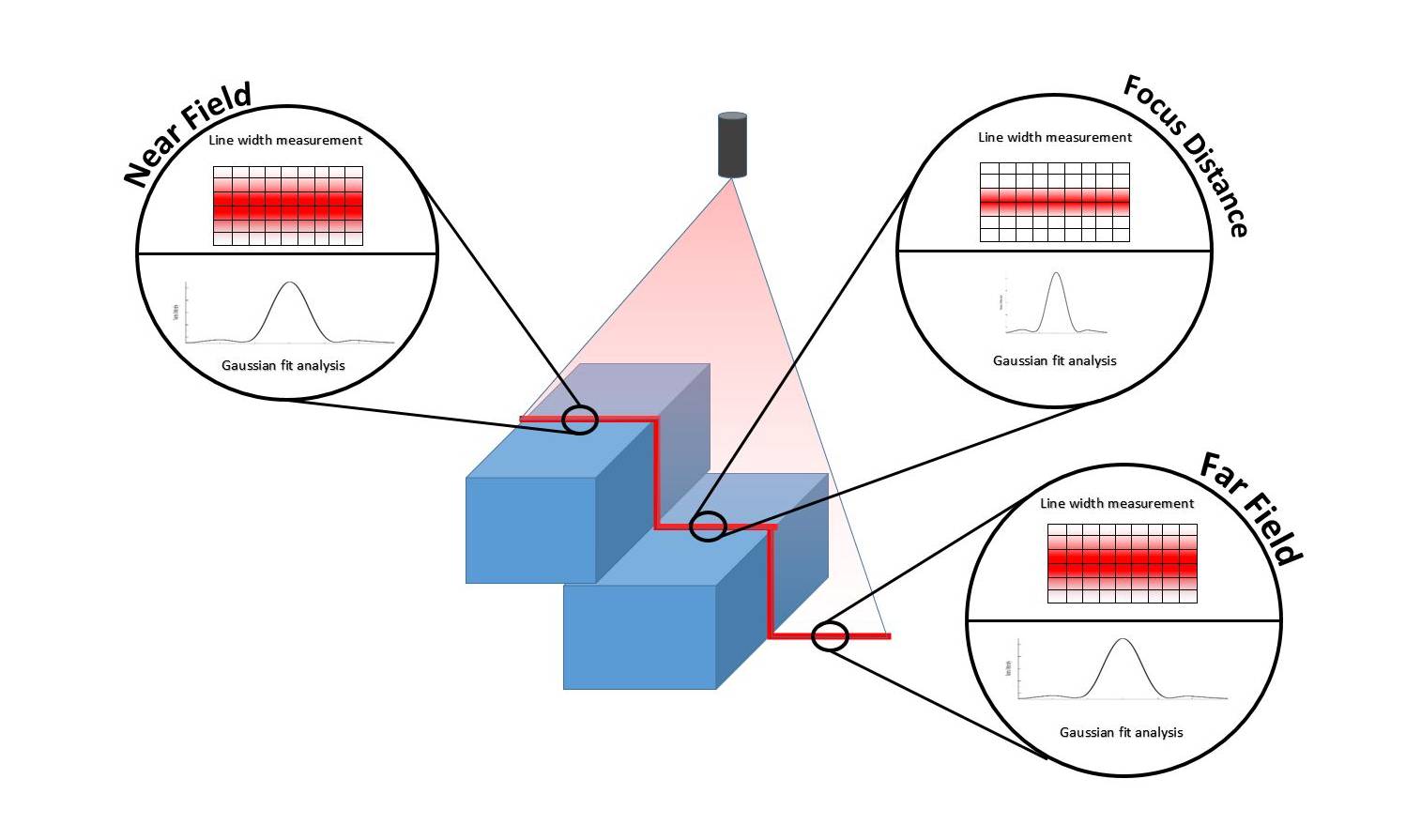

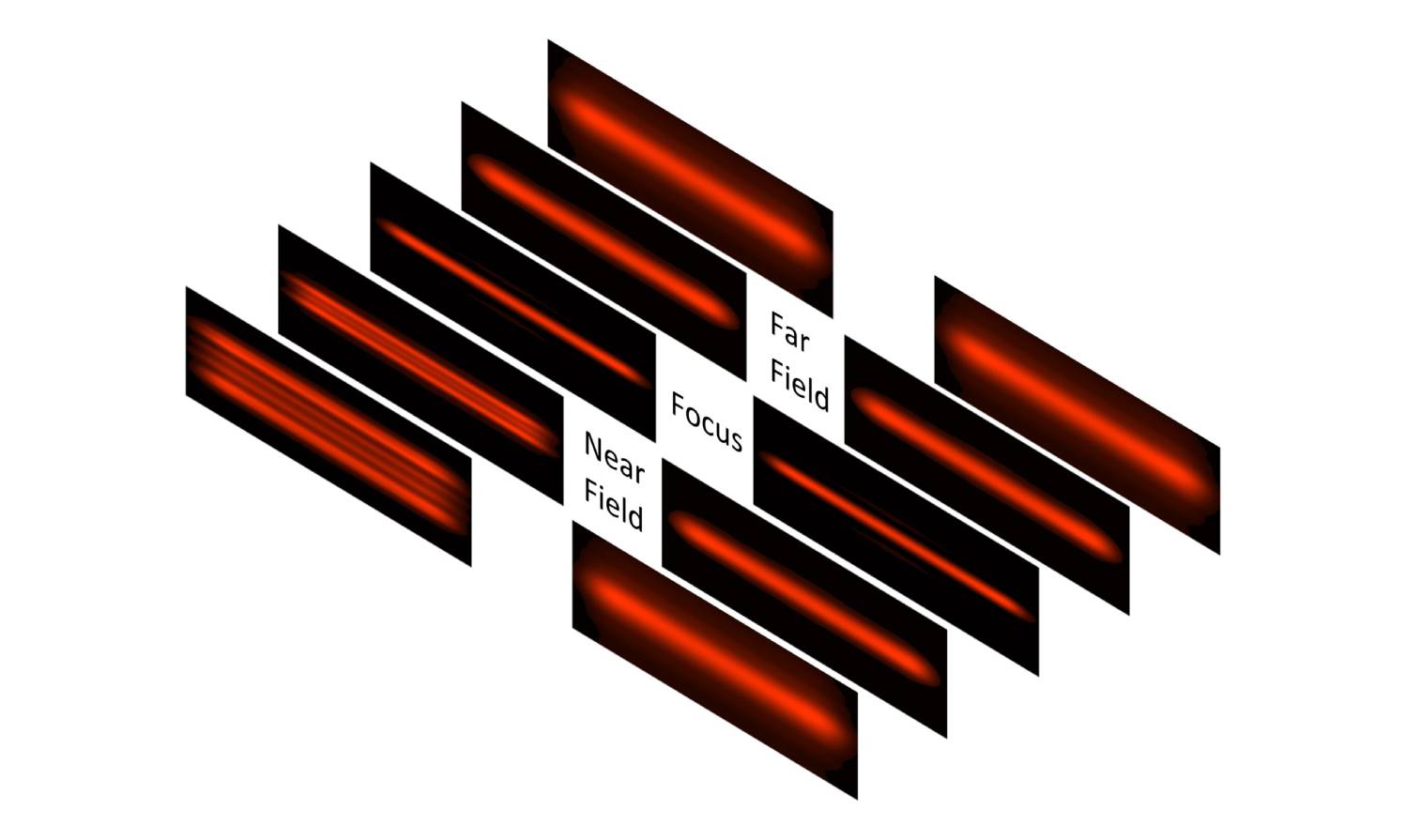

Focusing

Decades of experience in machine vision have shown us the importance of having uniquely optimized focusing performance for each application and system. We offer 10+ different focus options which can be tailored for best line thickness vs Depth of Field vs Gaussian performance in a given working range. In-house 3D focusing and measurement setups allow us to optimize the focusing performance of each laser to guarantee repeatability for your system. We have also developed simulation software that can be used to test each focus options performance in any condition (osela.solutions – contact us for access.)

Expertises